Description

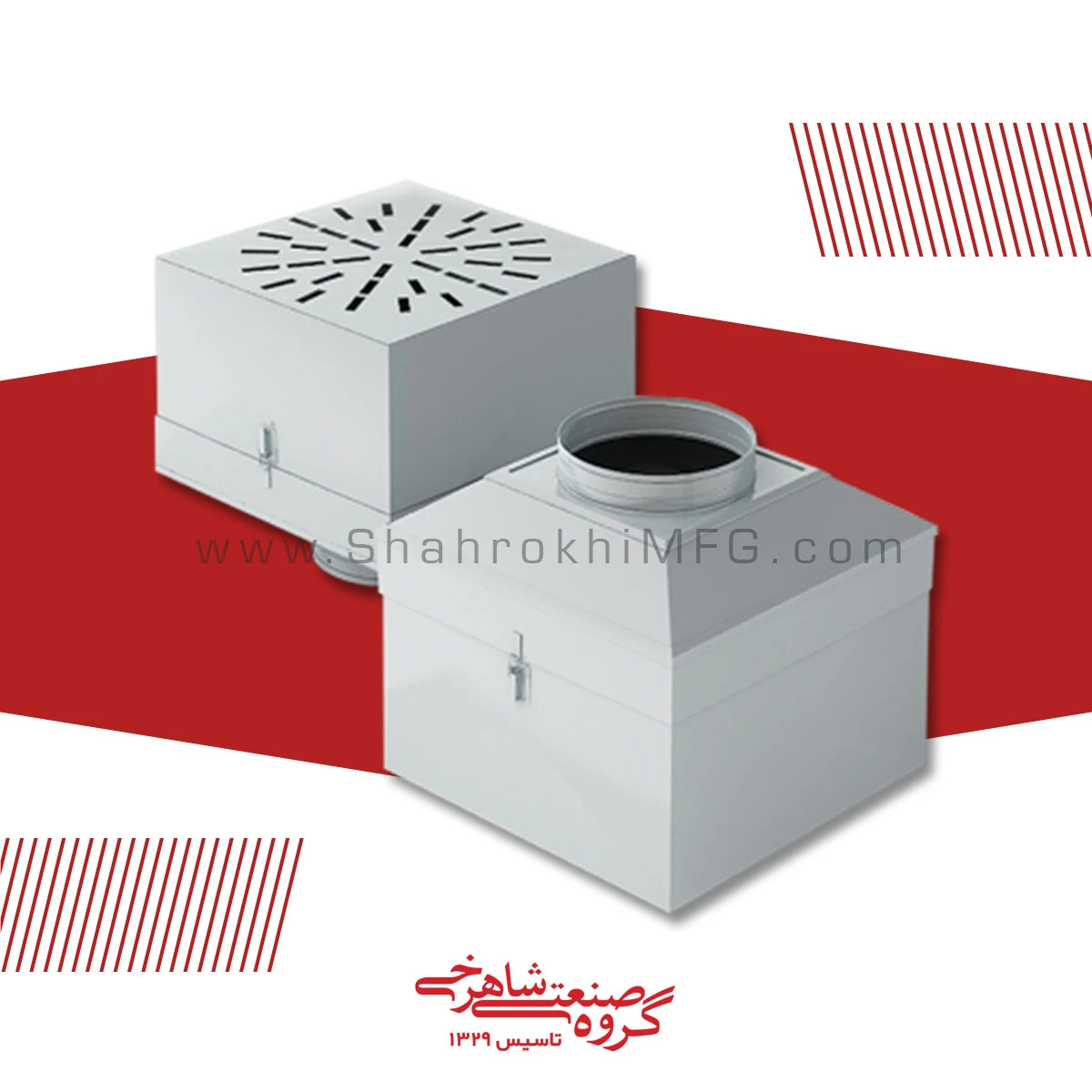

An overview of the HEPA filter box

The HEPA filter box is a complete set of air outlet or inlet equipment from the last point of air branching in clean room technology to meet the hygienic requirements of the environment. These boxes are one of the main elements used in cold and hygienic indoor environment conditions in clean rooms, which are classified according to ISO 14644-1 standard.

HEPA boxes include H13 and H14 filters. The inlets of the HEPA box can be adjusted as needed to provide the best hygienic performance in the environment. The filter box is a complete set of air outlet or inlet equipment from the last point of air branching.

Hepa box filter material

The main body of this product includes an air box (plenium box) made of steel sheet or galvanized sheet with static furnace color coating, in various and standard dimensions.

The solar valve is one of the components of these boxes, which is produced in different and diverse designs from aluminum with a furnace color coating for proper air distribution.

The filter that is installed inside the plenum box is the most important component of these boxes, which is placed inside the filter box of “HEPA” and “Alpa” type according to the use and class of the clean room.

Notable

In the design of the inlet and outlet valves as well as the air return in the clean room, they must be completely sealed and airtight so that the air is completely filtered and distributed in the clean room.

Features of the filter box body

- Body surface using electrostatic furnace paint, corrosion resistance

- Reservoir seal design for increased exclusivity

- Frame: cold rolled steel with coating or SS304

- Filter: HEPA filter mini-pleated seal gel or HEPA filter with separator

- Using the solar valve as a decoration of the filter box, which leads to optimal use in the proper distribution of ambient air.

- By placing the solar valve in the outlet of the filter box, it is prevented from throwing air in a heterogeneous, vertical and disproportionate manner.

- By creating a rotating flow in the air coming out of the filter box, the solar valve directs the filtered air to all parts of the clean room with appropriate acceleration and pressure. This feature allows the air to be evenly and proportionally distributed throughout the space of the room and to maintain the sanitary and controlled conditions of the environment.

- Choosing the right filter for the filter box that fits the class of the clean room is the most important issue in the use of the filter box. Failure to comply with this issue in clean rooms, especially operating rooms that require special filtering, can have irreparable consequences. Providing clean and controlled air in these spaces is of great importance, because any defect in air distribution and filtering can lead to an increase in the risk of infections and serious health problems for patients and medical staff.

Material of the sheet

- Cold coated steel, aluminum coated or SS304

Efficiency

- EN 1822: H14, U15.

- MPPS efficiency: H14: ≥99.995%.

- DOP efficiency: H14: ≥ 99.999%.

- Recommended final pressure drop: 600 Pa.

- Temperature: maximum 70 degrees Celsius in continuous service.

- Test: 100% individually scanned to EN 1822.

Application of HEPA filter boxes

hospitals; Operating theaters and operating rooms, special care, sterile areas, etc.

laboratories; Clean work areas and places, exhaust air filter from airborne particles.

industry; Electronic, optical, pharmaceutical, food and chemical industries.