Air curtain simple and effective solution to reduce energy consumption

ArticlesWhat is an air curtain?

The air curtain is used as one of the air conditioning devices in buildings to reduce the dispersion of air flow through the traffic areas of the building and to improve the performance of other ventilation equipment.

Air curtain is a simple and effective solution to reduce energy consumption

The air curtain creates a surface of high velocity air that is thrown down the open door or across other open surfaces. Air flow is created by a number of fans that are usually installed on top of the door. The air curtain is also a very good barrier against the entry of insects, rain, wind, and dust from outside into the building.

The right choice of an air curtain can be a very good factor in reducing energy consumption and increasing the performance of air conditioning systems.

In this article, while introducing the air curtain, the performance of this device has been checked to determine the advantages of using it. Also, the most important main factors in designing a suitable air curtain are given.

How the air curtain works

The main parts of an air curtain are motor, fan, launch nozzle and controller, which have different power and dimensions according to the operating conditions. Air is sucked from the inside or outside of the building by fans, which can pass through the hot or cold coil. Then it comes out of the nozzle at a high speed and covers the open surface.

Generally, their dimensions are from 1 meter to 3 meters, which cover the height from 2.75 meters to 4 meters. The air speed in them is from 3.5 to 15.25 meters per second, which is produced by powerful engines of 0.48 to 4.7 kW.

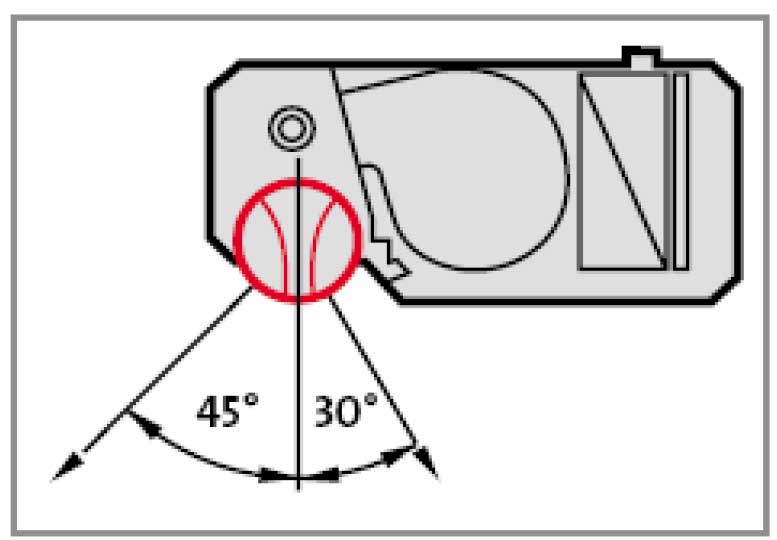

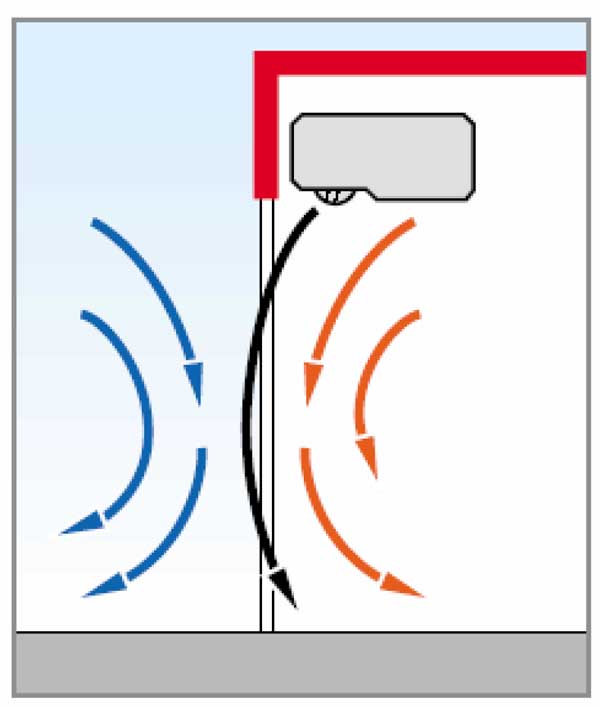

Air curtain cover angles

The thickness of the produced air curtain is from 2 to 5 inches, which is thrown towards the outlet at a suitable angle. The most suitable size of the launch angle is between 20 and 30 degrees. (opposite figure)

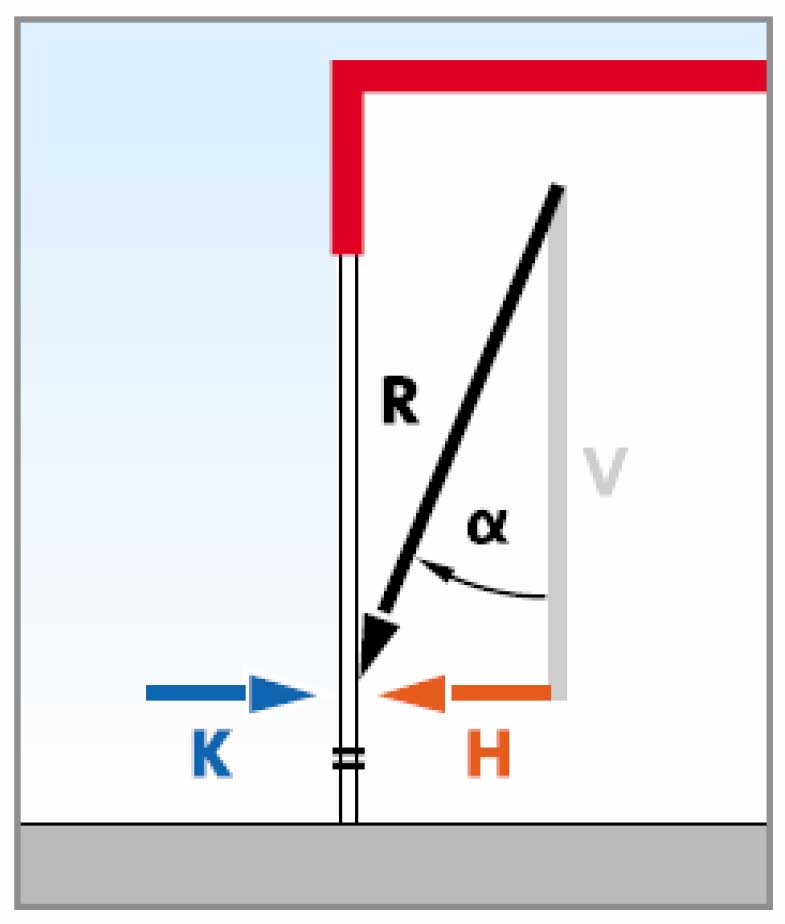

Blowing air out and preventing energy exchange

The air curtain makes the ventilation devices that are near the exit work better and reduces the heat and cold consumption in the building. This system reduces heat losses in the building by throwing warmer air from the higher level of the building.

Using a heating or cooling coil is not always economical due to the important energy consumption inside the coil, and in most applications, the same air inside or outside the design is used for launch. All of the above will eventually lead to a reduction in energy consumption. (opposite figure)

Types of air curtains

Today, air curtains are produced in various types with different functions

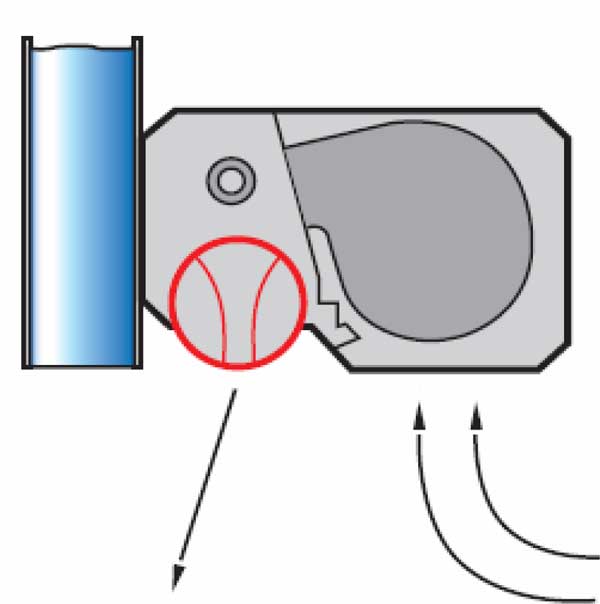

- Air curtain with suction of heated air inside

- With suction from the air inside

- Compound with suction from inside air

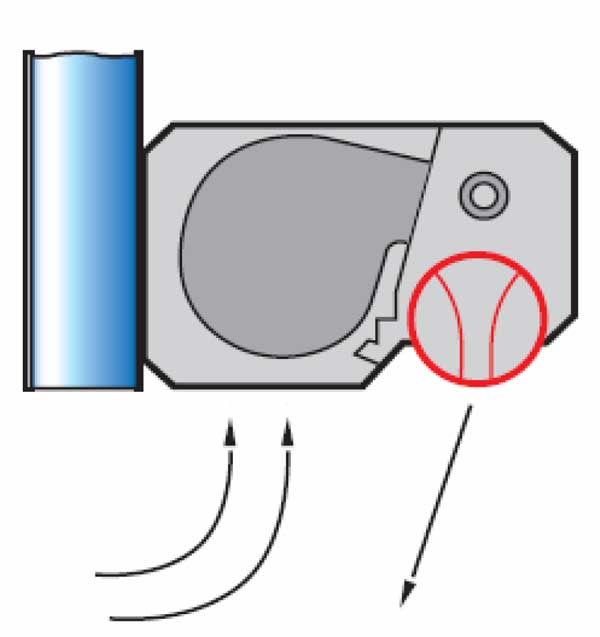

- With suction from outside air

- For head rooms

- For doors with high traffic

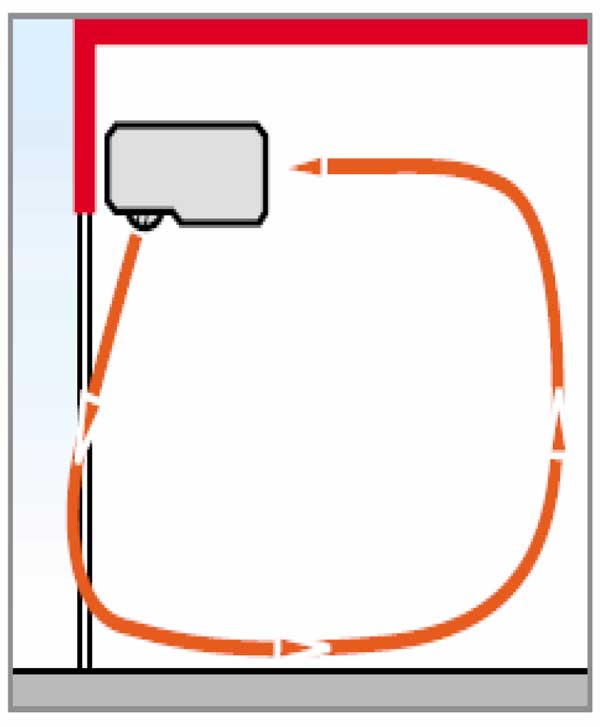

Suction of conditioned air inside and ejection from the nozzle at an angle towards the outlet

The first four rows of air curtains are installed at the exit of heated or cooled rooms that must be kept at a standard temperature. In all cases of this device, it is a uniform jet of air that is thrown at the right angle towards the open area. They are used for relatively small doors with dimensions up to 3.6 x 3.6 meters.

Suction from the outside air and ejection from the nozzle at an angle towards the outlet

Mixed air by throwing heated and unheated air at an angle of 15 degrees from each other reduces costs and rational use of energy. This type of air curtain preserves thermal energy by 25-60% and reduces costs by 30-70%, which depends on the dimensions of the door and the weather conditions of the area.

Air curtains for cold rooms are used in all kinds of cold rooms and rooms that are artificially cooled, such as vegetable and fruit storage areas, cold rooms, freezers, etc.

Preventing the air curtain from exchanging energy between two environments

The air curtain for high-traffic doors uses the feature of releasing free air with atomic pressure, 60% of the total cooling energy in a store is spent on ventilation, 80% of it is spent on overcoming the hot incoming air. Also, in factories and production halls that are not far from the office or other clean areas, using this system is a very good barrier to prevent the air from entering the hall into the clean area. The efficiency of this work is 70%.

The movement of the air coming out of the nozzle in the environment

Among the other uses of the device, it is used in paint rooms to prevent paint from splashing into the outside environment or in furnaces, it prevents the waste of furnace heat, and as a result, reduces fuel consumption. The air curtain itself is considered an energy consumer, but this factor should be compared with its performance.

Air curtain effect

The effect of the air curtain in preventing energy wastage is 60 to 80 percent. This value will be evident by comparing two places where one is installed with an air curtain and the other is without an air curtain.

Lawton and Howell in 1995 performed a utility analysis on air curtains for different doors in hot and humid climates. Two factors of pressure changes in two environments and working height were influential in choosing the right air curtain.

Due to the very good performance of the air curtain in reducing energy consumption, its use has become mandatory in most developed countries. Also, calculations related to the design of a suitable air curtain are given in most ventilation books.

The main factors in air curtain design

The speed of air exit from the air curtain is calculated by the following equation:

The formula for calculating the speed of air exit from the air curtain

where V0 is the air outlet velocity in fpm

Δp is the average pressure difference between outside and inside air near the open air curtain door

ƒ The ratio of the air exiting from the air curtain to the door surface for the mixed air curtain with outside air is ƒ from 10 to 20 and for the normal air curtain from 20 to 40.

β0 is the homogeneity of the air exit along the nozzle of the air curtain and is from 1.05 to 1.1.

Ρ the density of the air blown by the air curtain

E dynamic coefficient of the air curtain, (table of dynamic coefficients of the air curtain)

g acceleration | gravity

The air flow coming out of the air curtain is obtained from the following equation:

G0 = pV0A0

We get the temperature of the blown air using the temperature balance equation. (table of m1 and m2 coefficients):

t0 = tout + m1(tmix – tout) + m2(toz – tout)

where Tmix is the temperature of the normal air mixture and m1, m2 are the air curtain coefficients obtained from the following table:

Table of dynamic air curtain coefficients

Table of m1 and m2 coefficients

Reference:

2- “Development and Evaluation of an air-curtain fume cabinet with considerations of it’s aerodynamics.” R.F.Huang, Y.D.Wu, 2006

4- Fan Handbook: Selection, Application, and Design. By Frank P.Bleier.

5- ASHRAE HAND BOOK, Application

6- Industrial Ventilation Design Guide book. By Howard D.Goodfellow

Leave a Reply

Want to join the discussion?Feel free to contribute!