Description

Jet Nozzle Round Diffuser

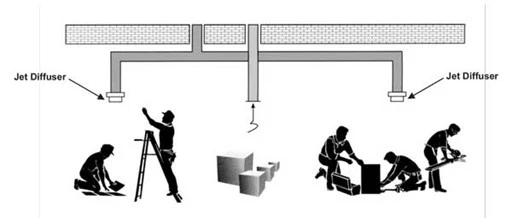

The proposal of Shahrokhi Industrial Group for long distances from the air exit point of jet nozzle Diffuser from the group of ceiling Diffusers with long throw is a suitable choice for spaces where there is a need to transfer ventilation air.

Shahrokhi Industrial Group’s proposal for long distances from the air outlet, jet nozzle Diffusers from the group of ceiling Diffusers with long throw, is a suitable choice for spaces where there is a need to transfer ventilation air. Why should we choose a jet nozzle Diffuser?

- No drop in air pressure and volume

- Air ejection uniformly

- Air distribution in high volumes

- Throwing air vertically up to approximately 20 meters

- Being quiet in the ventilation

- Determining ventilation angles by changing the direction of the blades

- Use of aluminum sheet in construction

- Can be installed on any kind of decorative frame, branch channels and plenum boxes

became.

Application of jet nozzle Diffuser

Jet nozzles are designed for large spaces that require a long launch, to shoot high volumes of air. These vents can be used on the ceiling (vertical projection) or on the wall (horizontal projection) in industrial environments such as production halls and theaters, stadiums, halls, arcades, etc.

Features of jet nozzle round Diffuser:

- The ability to direct the air flow to the desired point in the cold and hot seasons of the year (centralized air distribution with the ability to adjust in all directions)

- Changing the direction of the opening of the valve based on the direction of hot air (throwing downwards due to the rising nature of hot air) and cold air (throwing upwards due to the descending nature of cold air)

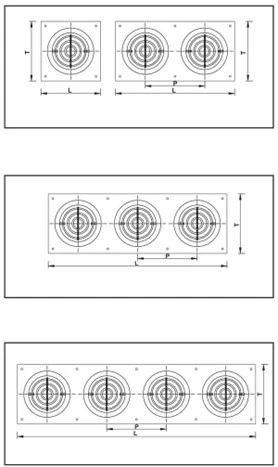

- The ability to provide square elements in the form of single element to four elements, which is capable of injecting a large volume of air into the environment (placed in the box in the types of one, two, three and four elements)

- Capable of aeration up to 8000 feet per minute

- Standard nominal diameters 100-125-160-2-250-315-400 and… for aeration from 54 to 1440 cubic meters per hour

- The ability to adjust the current output from -30 to +30, made of high-quality aluminum sheet

- The final coating of these valves is made of electrostatic furnace colors (each color is different for each metal).

- A beautiful and stylish appearance for use in facing channels

- The ability to throw the exhaust air at least in the arc of 60 degrees due to the type of design (the presence of the axis in the middle of the parallel blades)

- Exiting and throwing air into the environment with the greatest acceleration, due to the vertical and successive blades of the nazzle jet Diffuser

- Air transfer of vertical and horizontal degrees in a concentrated and point-like manner due to the blades and vanes being connected to a point or focus.

- Energy saving for large and high environments

- They have the ability to change the flow up to 30 degrees only around one axis (unlike the jet diffuser valve, which has the ability to change the direction up to 30 degrees in all directions)

Jet nozzle diffuser installation requirements

As with most of the valves produced by Shahrokhi Industrial Group, this product is installed using automatic screws instead of screws, before applying the paint coating on the valve frame. It is recommended to install this valve on a wooden or metal frame, and by directly installing the valve on plaster, there is a possibility of the valve loosening over time. It is worth mentioning that to install this valve on false walls with dry materials (Kenaf, etc.), special false ceiling profiles must be used around the opening of the valve for strength and reliable connection of the valve to the wall.

Valve material and color

Frames are made of 1.5 mm thick aluminum profile and 1 mm thick aluminum sheet with good quality anodized aluminum coating.

Also, plenum boxes are made of aluminum sheet with a thickness of 1.5 mm.

It is possible that the final painting can be done by spraying liquid or powder paint (electrostatic) using white polyester of any other color with a certain ral number according to the need.

Product order code

Shahrokhi’s round jet nozzle damper and non-damper ceiling diffusers are identified by the order code below.

SH: Shahrokhi factory

RDI: Round roof hatch

JN: Jet nozzle

NP: the number of valves inside the plenum box