VAV Systems

VAV Systems

The main purpose of any HVAC system is to provide comfort. Comfort in a place depends on the combination of temperature and humidity. The HVAC system requires a certain amount of supply air to provide a significant combination of humidity and temperature within the comfort zone. About 60 to 70 percent of the energy consumed by buildings is used for ventilation and exchange of building air with the outside environment.

Therefore, one of the most appropriate ways to optimize energy consumption in buildings is the use of VAV systems.

VAV stands for “Variable Air Volume”. VAV is a ventilation control method and is used in buildings where the thermal or ventilation load is always variable. As the number of people in a room changes, the air quality (temperature, humidity, carbon dioxide) also changes, and this is done by placing an air quality measurement sensor such as CO2, temperature or humidity… which are good indicators of air quality. are adjusted.

Also, when heat sources such as the number of people, computers, and sunlight cause the heat load of the room to increase, it is necessary to cool or heat the room with an air conditioning system.

These things are always changing during the day and night and must be controlled by the ventilation system. By implementing the VAV system, temperature control conditions with variable air volume are provided.

Today, VAV systems can provide changes in the cooling and heating load required by the building. For this purpose, in VAV systems, a fan with variable speed is needed, which saves energy and cost to a great extent by reducing the power of the fan. The VAV system controls different loads in the rooms by opening and closing the air damper inside the mixing chamber.

VAV systems are divided into two categories:

Pressure dependent systems

Pressure independent systems

Pressure dependent systems:

In these systems, a motor damper is placed on the air damper entering each space, which controls the closing rate of the damper according to the temperature inside the room and the command received from the room thermostat.

Since the closing or opening of each damper affects the amount of static pressure in the duct and will cause a change in the amount of air passing through other dampers, therefore, this method depends on the static pressure inside the duct.

Pressure independent systems:

In this method, a VAV box is placed in each area, which is connected to the air distribution channels. The VAV box can adjust the volume of air entering the space or room according to the volume of passing air.

The temperature of the air outlet of the air conditioner is controlled and adjusted to a certain level. This certain amount of temperature is not constant and it is optimized by monitoring control and its set point is reset.

In the pressure independent VAV system, the volume of air entering the spaces changes to compensate for the cooling load based on the command received from the room unit.

In parallel and in accordance with the change in the volume of air poured into the room, the volume of air coming out of the air conditioner fan should also be adjusted.

It should be noted that in the VAV system, the opening or closing of the dampers is independent of the pressure, and it is the amount of air entering the rooms that is controlled.

Comparison of CAV system with VAV system

- CAV system works based on variable temperature with constant air volume, but VAV system works at constant temperature with variable air volume.

- In the CAV system, all the equipment works at maximum capacity, but in the VAV system, the equipment works based on the need.

- Depreciation of devices in VAV system is lower than CAV system.

- Sound pollution (noise) resulting from fan operation in VAV system is less than CAV system.

- The possibility of temperature control in VAV system is more than CAV system.

- Humidity control is not possible in the CAV system, but it is done in the VAV system.

- The amount of energy consumption in the CAV system is much higher than the VAV system.

VAV Systems

General information:

- Suitable for office, commercial, residential and laboratory applications

- Suitable for controlling air volume, room or channel pressure

- High control precision

- Suitable for air velocity between 2 and 10 m/s

Advantages of the system: VAV

- Ability to control temperature and humidity

- Reducing the depreciation of related equipment such as fans and compressors

- Reducing fan energy consumption

- Creating less noise in the system

- Return of the initial cost in a short period of time

VAV Systems

Types of VAVs manufactured by Shahrokhi Industrial Group:

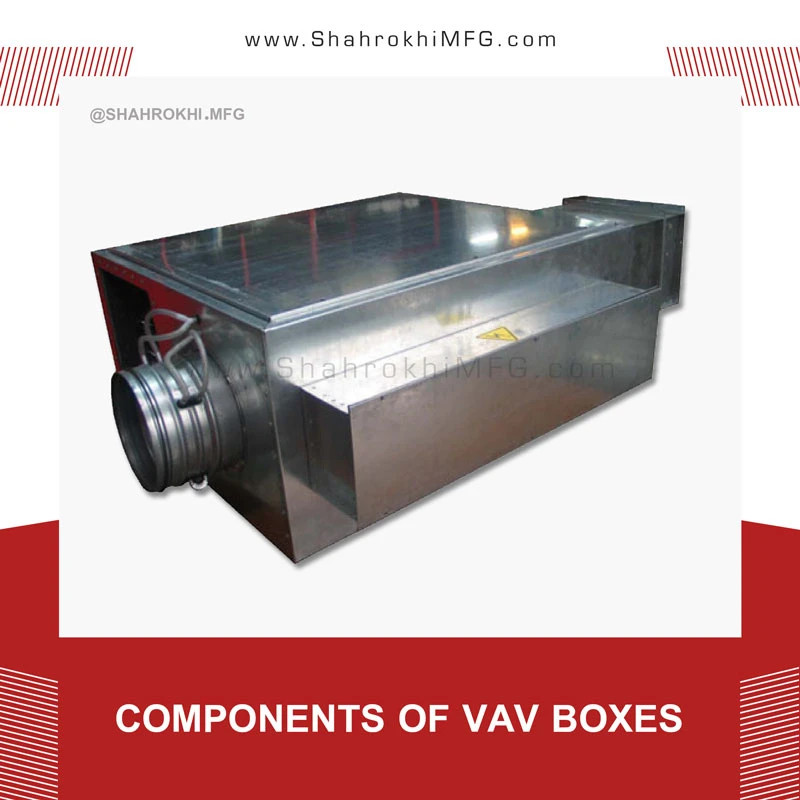

- Rectangular or square VAV box damper

- Circular box VAV damper

- VAV box damper with acoustic body (rectangular, circular)

Rectangular damper components: VAV

- Body with galvanized steel sheet

- Opposite air foil model aluminum blades

- Aluminum probes for measuring the pressure difference on both sides of the flange

- Power transmission system for the movement of the blades, a gear model made of ABS plastic

- Galvanized steel shaft

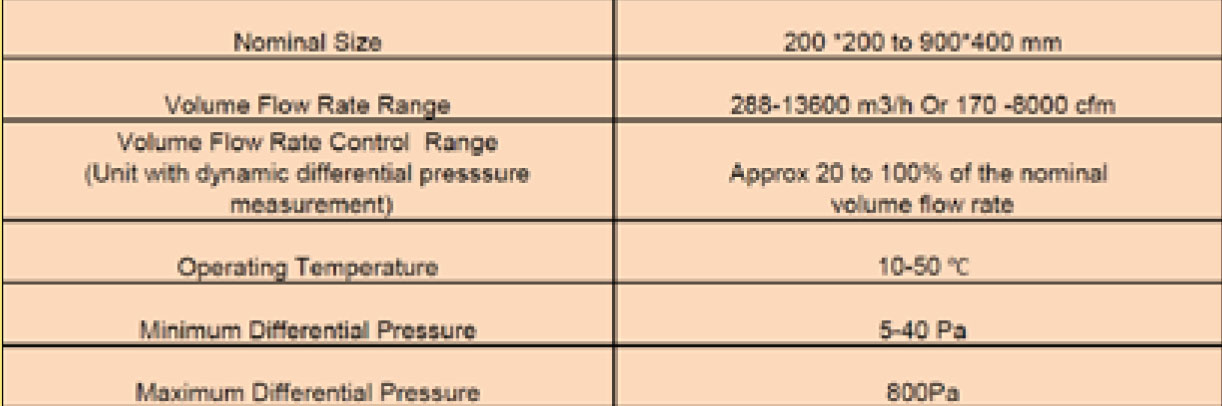

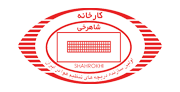

Rectangular VAV technical specifications

Circular damper components: VAV

- Body with galvanized steel sheet

- Single blade galvanized blade

- Galvanized pressure measurement probes

- Has air-tight rubber on both sides of the damper

- Without flange (it is possible to install flanges on both sides)

- Galvanized steel shaft

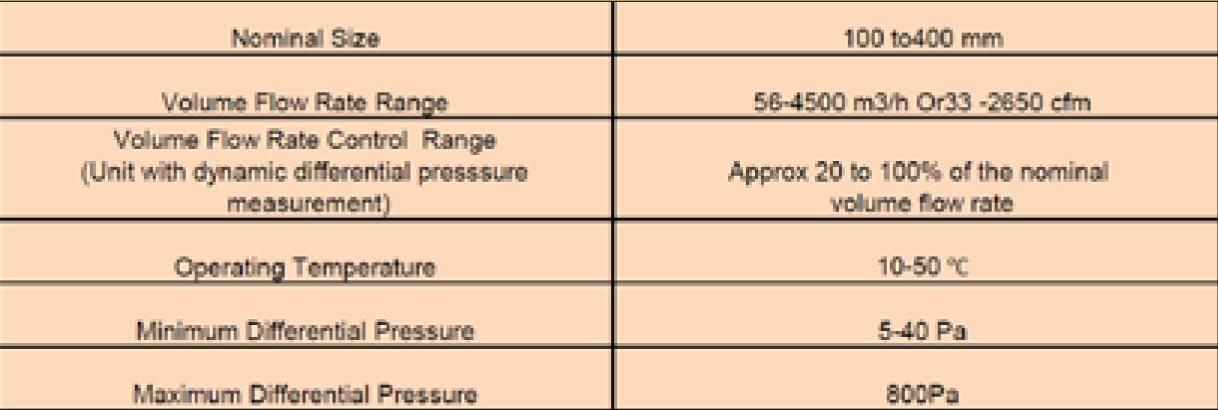

Technical specifications of round VAV

Damper control components: VAV

- PC-Tool software program for functional tests of air flow controller system

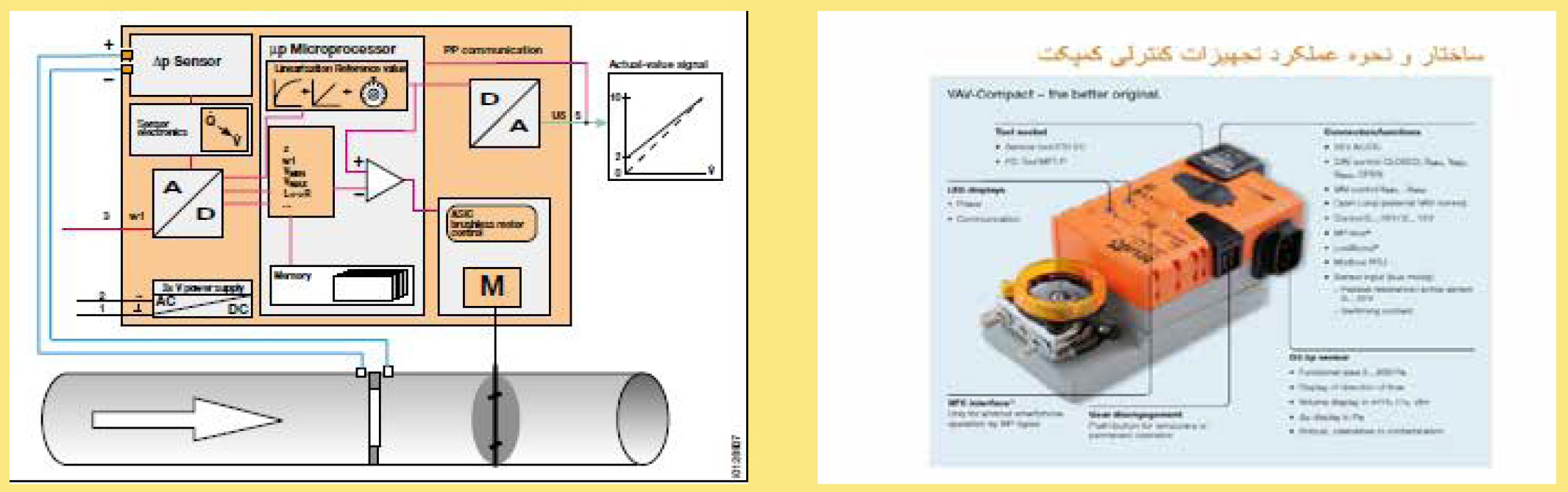

- Universal controller consisting of separate pressure difference sensor, separate controller and separate actuator for special applications

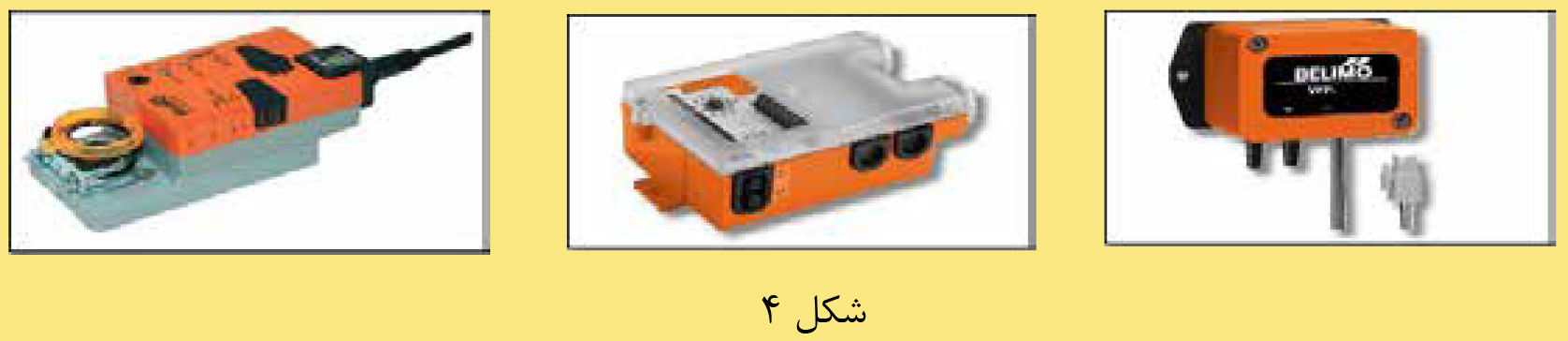

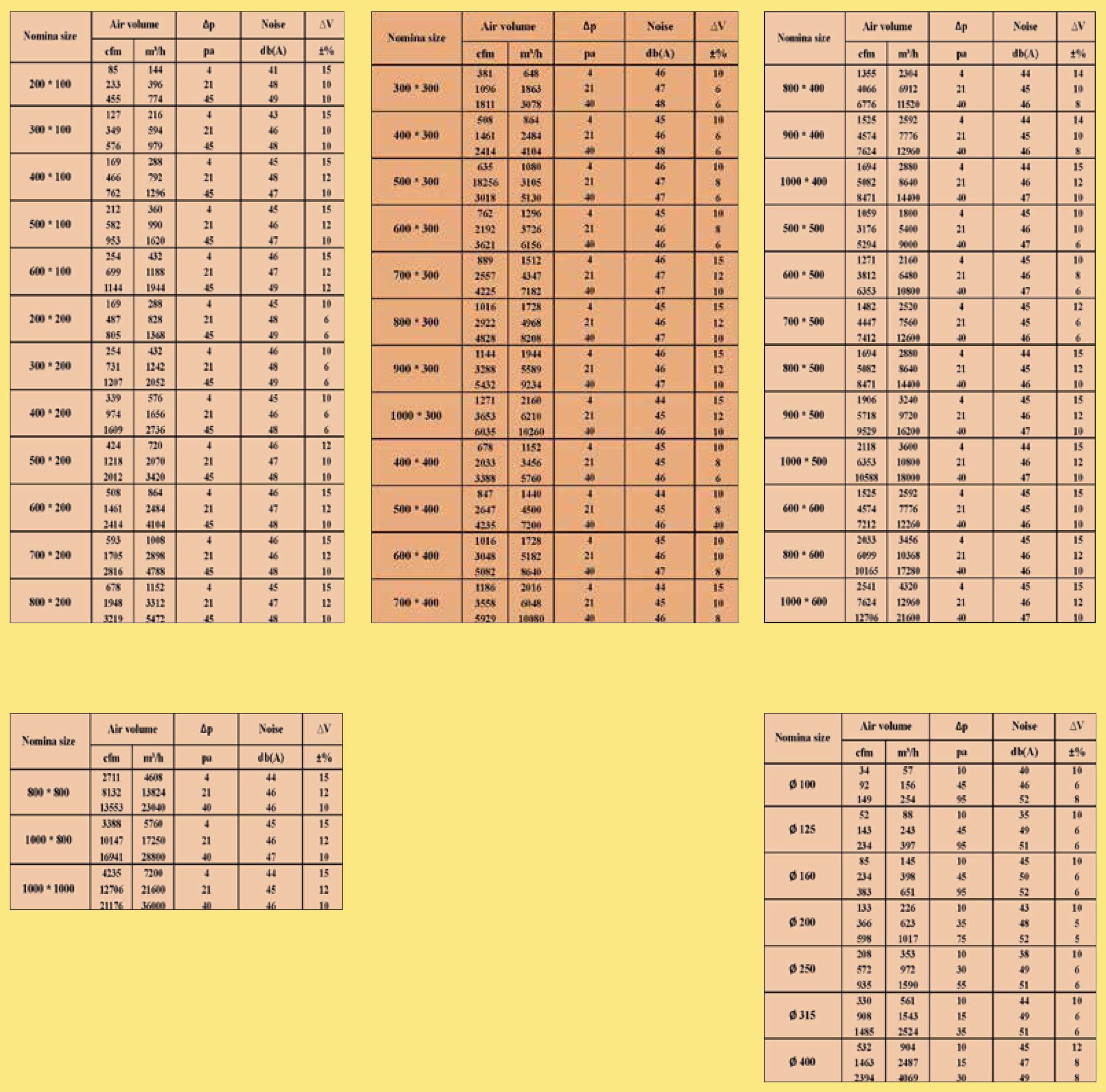

- Compact controller consisting of a pressure difference measurement sensor, controller and actuator in one place

Note: Compact controller is currently used in Shahrokhi Industrial Group.

VAV damper control components

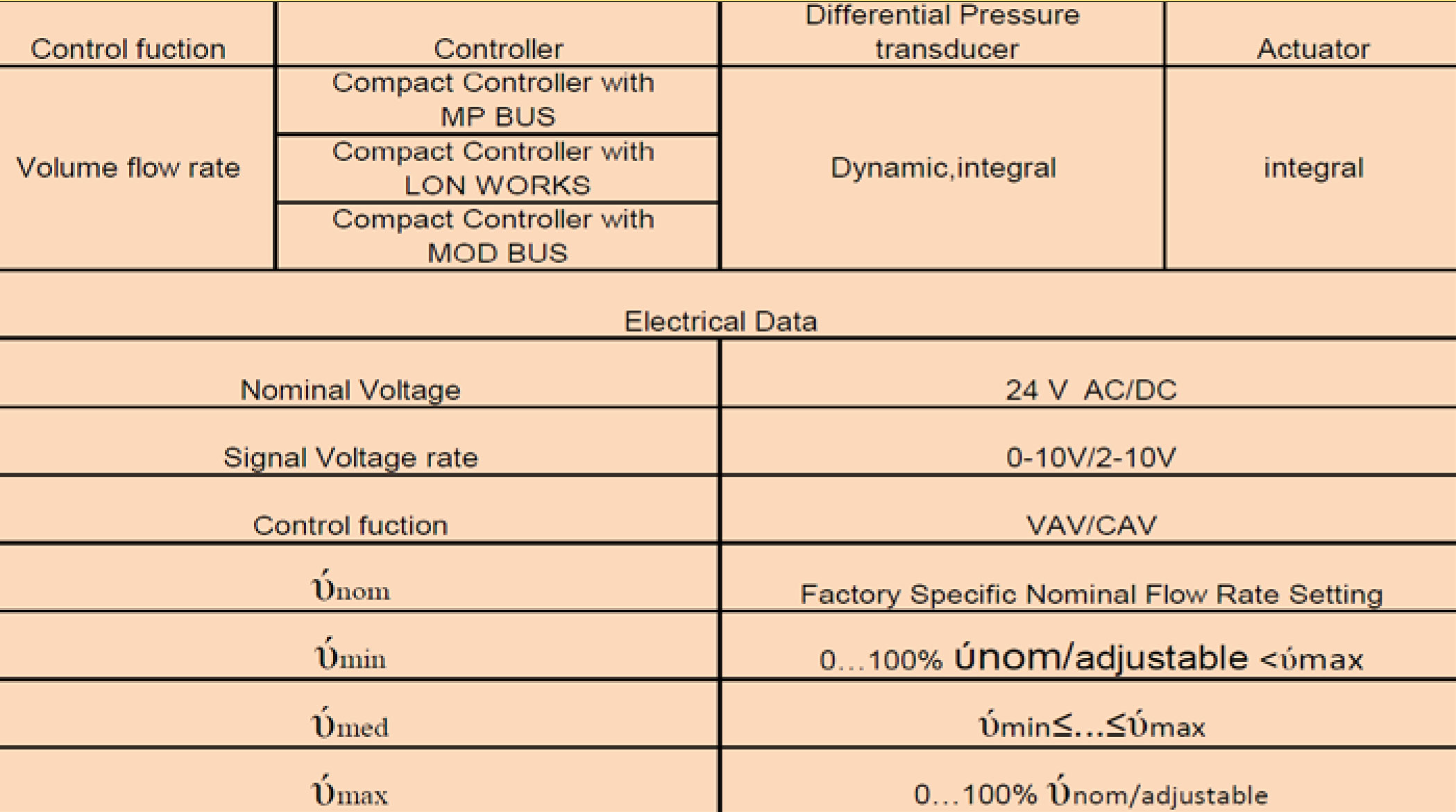

Table of technical specifications of the compact controller:

Table of technical specifications of compact controller

How the compact controller works

Technical specifications of dampers: VAV

Technical specifications of VAV dampers

Leave a Reply

Want to join the discussion?Feel free to contribute!