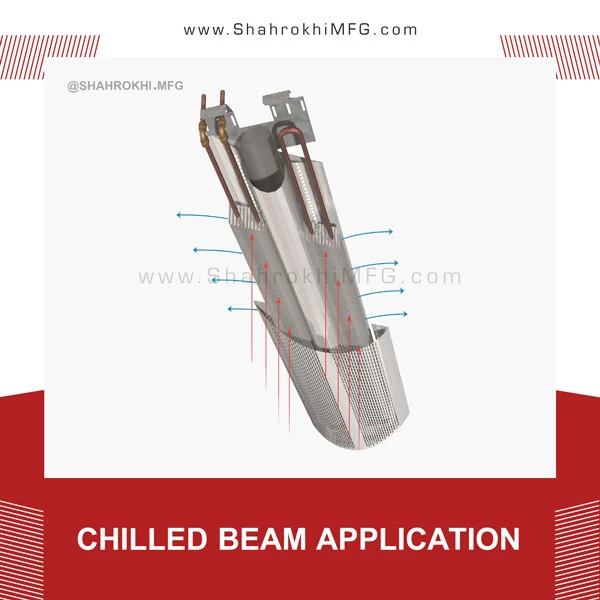

chilled beam application

The use of strong induction property in the example of active chilled beams has caused the complete elimination of the fan compared to the fan coils, which causes the complete elimination of sound.

About 20% of the incoming air in these systems is provided by the air conditioner, which has already been silenced, and the remaining 80% enters the Chilled beam from the environment by the induction property (suction) produced by the Chilled beam.

Another type of child beam is its passive type – or cooling ceiling panels – which are used to cool the ceiling.

The simultaneous use of radiation properties has a significant effect on the significant increase in the working efficiency of child beams, especially its passive type.

In this type of child beam, without the intervention of a fan, the hot air goes up by the natural convection current and after hitting the coil and cooling, it moves down freely without the help of a fan and cools the ambient air.

In each Chilled beam cooling unit – of passive and active type – the water temperature between 15 and 17 degrees Celsius is pumped to Chilled beam by the water system in order to bring the ambient air temperature to the appropriate level.

The temperature of hot water in Active Chilled beam type is about 500 C, which makes it possible to use solar energy for heating in winter.

Performance of child beams of Active model

The main design of this type of chilled beams is in such a way that fresh air enters special air discharge nozzles with dynamic pressure, and as a result, the static pressure, which is lower, causes hot air to be drawn from the room to the chilled beams.

Inside the Chilled beam copper tube, cold water is passed for cooling, which consists of aluminum fins (coil), heat is absorbed through aluminum and cooled by cold water. Then the ambient heat is transferred to the water circuit through the copper pipe and returns to a central cooling unit. Also, a heating function can convert cold water copper pipes to hot water and thus heating ventilation.

Performance of passive model child beams

The warm air inside the room is always on the surface of the cold air due to its lower density. The cold water passes through the cold rays of the child beam and cools the warm air above the room, and as a result, the cold air moves down due to its higher density (Drop phenomenon) and this cycle continues day and night to make the ambient air favorable. make

The general result is that these types of child beams can reduce the temperature of the environment without having a fan or even fresh air intake (optimizing energy consumption) and without making any noise.

In a cold rolling process, the copper tube is made efficient by metallurgical bonding to an aluminum sheet (Gills) which enables the transfer of energy from the cold surface to the water circuit and makes galvanic corrosion between the metallurgical bond of copper and aluminum impossible.

Leave a Reply

Want to join the discussion?Feel free to contribute!