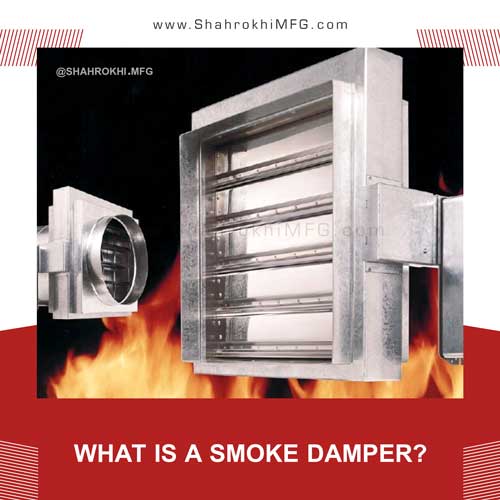

What is a smoke damper

smoke damper

The smoke damper is used to prevent the passage of smoke and to prevent the passage of smoke and gases resulting from fire to another area in the way of air passage channels. When a fire occurs at a certain temperature, it closes automatically and prevents oxygen from reaching the fire and the spread of smoke to other areas.

Smoke dampers are divided into two main categories:

-

Fuse damper

-

Motorized damper

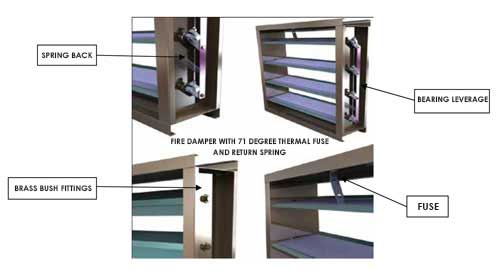

Fuse damper

The main components used in these dampers usually consist of fuses, vanes with a tube inside them, and brass bush type connections. The fuses used in this type of dampers are divided into two general categories: solder and alcohol. Solder fuses work at 71 degrees and alcohol fuses at 68 and 79 degrees. These fuses are used in the role of the steering system to block the path of the air channel.

In the novel “The Origin of Fire”, the thermal element in the fuse of this type of damper melts at a certain temperature and leads to the closing of the damper blades and preventing the spread of fire.

Fuse damper

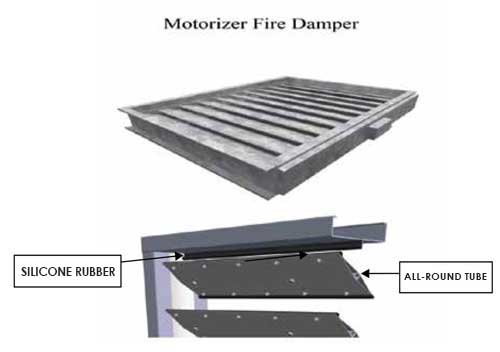

Motorized damper

The components of this type of dampers are the same as fuse dampers, with the difference that the driving force of the vanes is provided by a motor and smoke and heat sensors are used instead of fuses. In places that have high safety, a special form of this type of damper is used, which consists of bearing levers, bearing connections, motor, double curtains, a tube inside the vane and heat-resistant silicone rubber.

These components can also be disassembled. Motorized dampers are closed using signals received from smoke and heat sensors located far from the damper.

Motorized damper

Smoke damper test

Two parameters have a significant effect on the performance of fire dampers:

-

The amount of leakage

-

Fire resistance level

For this purpose, the fire damper must be subjected to two leakage and thermal tests for functional and resistance measurement, which will be described in the following process of performing these two tests.

The purpose of this test is to determine the leakage rate of the smoke damper and its compliance with the relevant standard. The leakage test is performed in two times, before and after the thermal test. Among the written standards for leakage testing is the UL 555s standard.

In order to perform the leakage test, the damper is first closed on the channel and the damper is exposed to pressures of 250, 500, 1000, 2000 pascals in a completely closed state, and the volume of air coming out of the damper is measured.

Note: Smoke dampers manufactured by Shahrokhi Industrial Group have class 1 leakage with UL555S standard.

Leakage test

Thermal test of smoke damper

The purpose of this test is to determine the resistance of the damper against the heat resulting from the fire and to evaluate the behavior of a damper sample that is exposed to a certain heat and pressure. There are written and valid standards to perform this test, including EN12101-3 standards.

How to perform the test in order of steps is as follows:

– Damper leakage test according to AMCA Publication 500D standard

– Damper installation on the furnace

– Damper mechanical inspection

– The damper is closed and exposed to radiant heat.

– The temperature of the furnace has reached 250 degrees and the system must be designed in such a way that it can remain at a constant temperature of 250 degrees for 90 minutes.

– After the damper has been exposed to heat for 90 minutes, the damper opening and closing test is performed.

– Heading of the damper when the vanes are open at ambient temperature

– Damper mechanical inspection

– Damper leakage test according to AMCA Publication 500D standard

– Preparing the final report

A view of the damper being thermally tested

In this regard, Shahrokhi Industrial Group, since 2007, in order to manufacture, test and install smoke dampers for ongoing projects in its laboratory by purchasing new devices and calibrating them, making the necessary channels, making furnaces, providing fans with the ability Provide static pressure behind the damper (according to the customer’s request). Shahrokhi Industrial Group carried out all the mentioned measures under the supervision of the Standard Department and in cooperation with the German GL Inspection Company, and finally succeeded in obtaining the approval of the German GL Company to conduct the leakage and thermal testing of fireproof smoke dampers.

Fire test

Leave a Reply

Want to join the discussion?Feel free to contribute!