What is Sound Attenuator

What is Sound Attenuator?

What is Sound Attenuator?

In the air conditioning ducts, generally, due to the operation of the fan, whether axial fans or centrifugal fans, an unpleasant sound is dispersed in the environment. The intensity of this noise varies depending on factors such as the type of fan, the distance of the fan from the location, the type and type of channels and branches, the type of surrounding walls and other such factors, but in any case, the presence of this noise will create a disturbing environment for the residents.

Nowadays, channel Sound Attenuator are used to solve this problem. With their special design, these Sound Attenuators, in addition to having the least impact on ventilation air flow, eliminate the sound produced by air conditioners to a great extent.

Silencers are widely used in industries such as metallurgy, electricity and power, mining and subway tunnels, and interior architecture in order to reduce HVAC system noise. The type and design of Sound Attenuator is such that it absorbs the noise produced with all kinds of frequencies and in the range of human hearing (from 63 Hz to 8000 Hz) it provides comfortable environmental conditions in terms of sound.

In this regard, the design of a suitable silencer that can provide these conditions in the environment is of special importance in such a way that in the case of improper design, the silencer will be able to absorb sound and as the cause of sound, it will double the problems. The basis of sound absorption in sound absorbers is based on the absorption of waves in porous materials.

Porous absorbent material

Sound absorbent materials absorb most of the sound energy and reflect a small amount of it. Therefore, the use of these materials is very useful to control the amount of noise, and they are used in various places such as points close to sources of noise production (such as fans in air conditioning systems) and inside air transmission channels.

There is a wide range of these materials that provide a variety of absorption properties based on sound frequency, composition type, thickness, outer surface, and installation method. Meanwhile, materials with high sound absorption coefficients are usually porous. A porous absorbent material is a solid that contains holes, channels, or slits that sound waves are able to enter.

Stone wool is among the family of thermal insulators consisting of mineral fibers. This insulation is a very desirable sound insulation due to the absence of sound transmission among the components and sound absorption, therefore, it is installed in airports, sound recording studios, under rails and in metro stations in cities. Increasing the thickness and creating a suitable air gap behind the insulation increases the amount of sound energy attenuation.

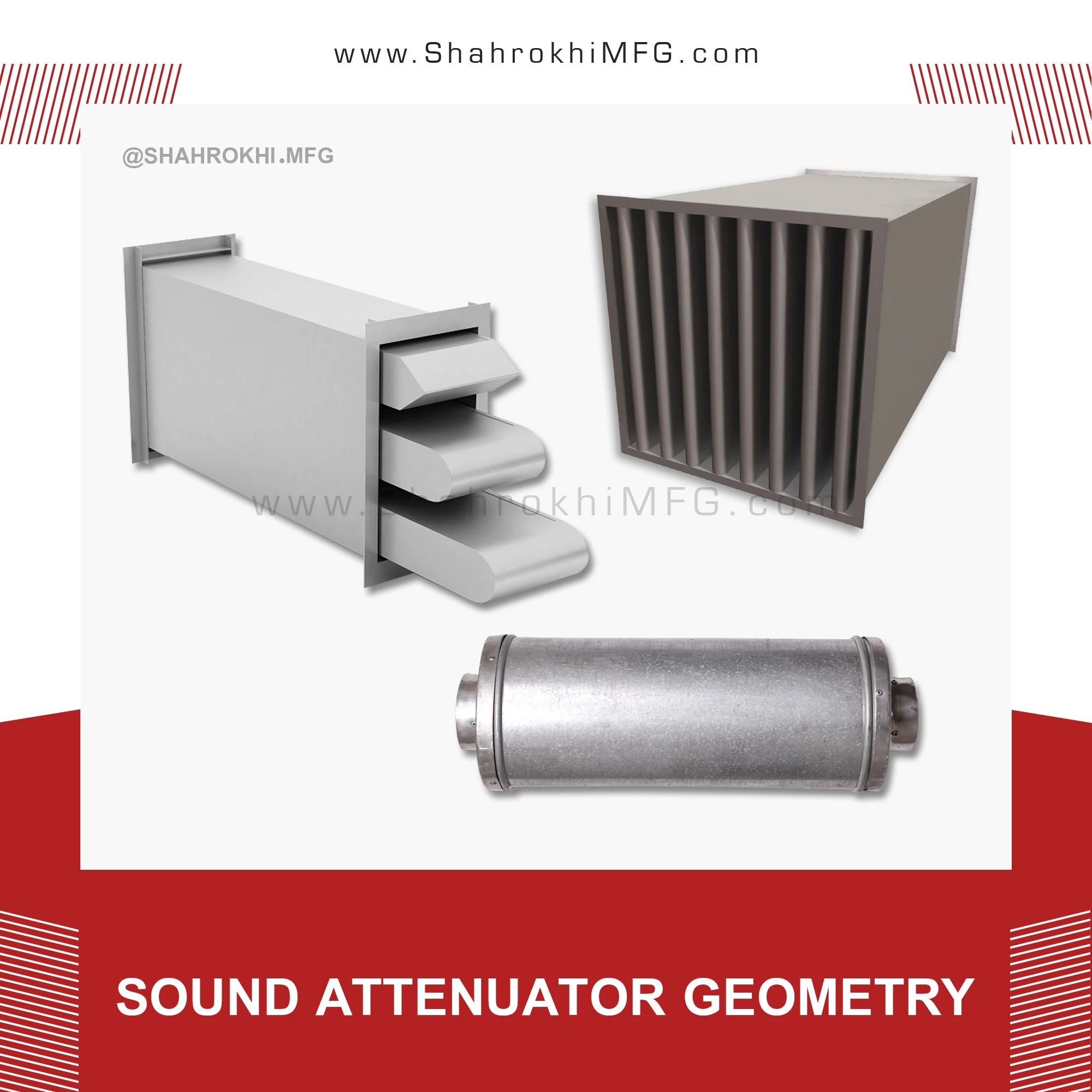

The geometry of Sound Attenuators

The structure of Sound Attenuators includes perforated sheets, where porous materials are placed between the two sheets depending on the place of use. Sound absorbers that are used in most cases today are in the form of vertical blades with specific length and width. Blades placed next to each other with equal distances in the ventilation channels.

Therefore, the passing air flow passing through these blades by means of two surfaces and the sound absorbing properties of the porous materials in the body of the blade, lose their accompanying sound to a certain extent. These Sound Attenuators have advantages, among which one can mention stability against air flow and wind speed, as well as the ability to replace damaged modules.

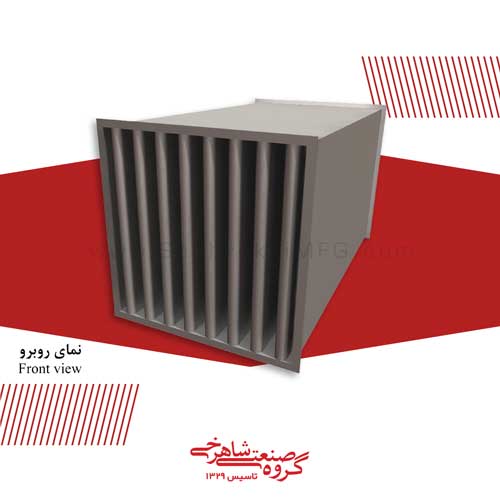

Sound Attenuator Front View

Sound Attenuator Back View

Leave a Reply

Want to join the discussion?Feel free to contribute!